6N Copper Ingots

Ultra High-Purity 6N Copper Ingots (99.9999% – Oxygen-Free)

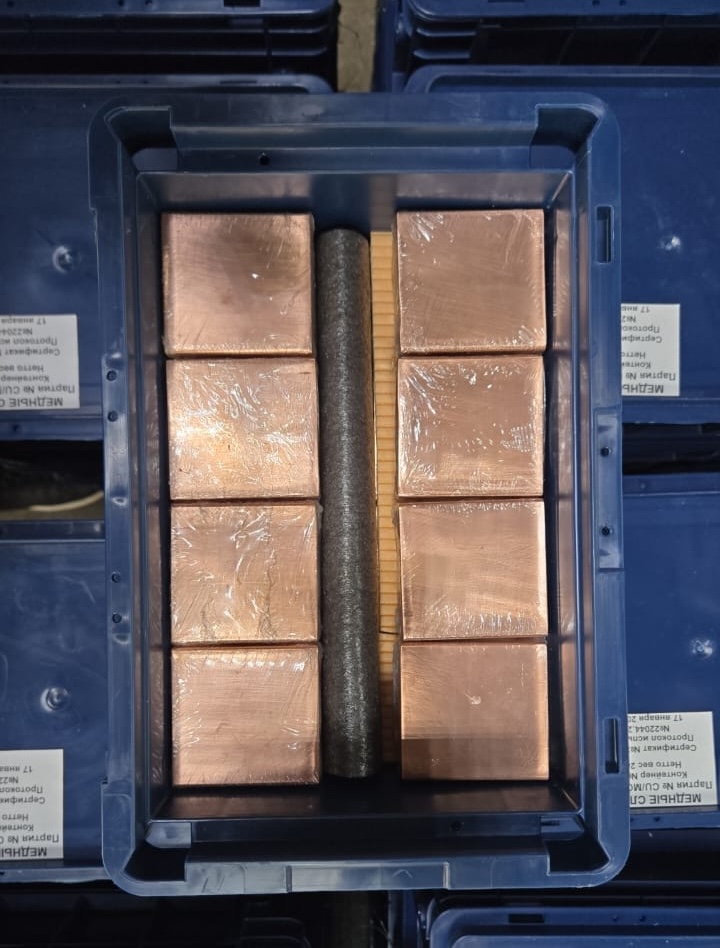

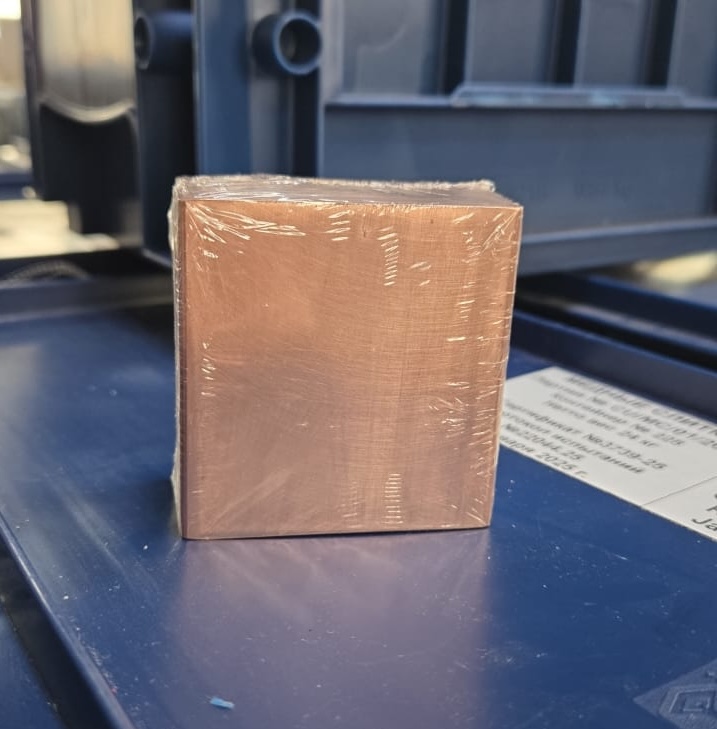

Fine 1 kg copper ingots, each individually sealed in polyethylene wrap to prevent surface oxidation.

Product Gallery

Product Details

Real FAQs

Yes, trial orders are available for most products, excluding custom-engineered alloys. Please select the “Trial quantity required” option when submitting your RFQ form.

Lead times vary depending on the type of order. Below is an overview of typical processing and delivery times for our main order categories:

- Trial batch orders are typically dispatched within 5 business days from the date of payment receipt.

- Ultra high-purity metals purchase orders are fulfilled within 7–14 business days from the date of advance payment under the main agreement, depending on quantity and destination.

- Custom alloy wire manufacturing orders include a development phase and are scheduled individually based on product complexity, specification, and volume.

Lead time for each custom alloy wire contract is determined jointly with the client and includes both production and quality assurance stages.

Yes, we can arrange logistics and deliver to any international airport specified by the buyer.

Our order processing follows a structured and transparent workflow aligned with Incoterms 2020 practices:

- Client: submits an LOI (Letter of Intent) or RFQ form to Pure Metals.

- Jointly: we clarify and confirm all technical and commercial details of the LOI/RFQ.

- Pure Metals: issues an FCO (Full Corporate Offer). We intentionally skip SCO (Soft Corporate Offer) to streamline the process.

- Client: confirms the FCO and provides proof of funds (BCL or equivalent banking document).

- Optionally: a trial quantity shipment may be arranged under an accelerated procedure, based on a simplified standalone agreement. Upon receipt, the client confirms that the product quality meets the required specifications.

- Pure Metals: drafts the contract and coordinates revisions with the client.

- Both parties: sign the final contract.

- Client: makes a partial advance payment — typically 25% of the total value of the initial product batch.

- Pure Metals: dispatches the goods and provides the transport documentation to the client.

- Client: completes final payment and receives the goods at the destination in accordance with the transport documentation and agreed delivery terms.

Absolutely. Once your RFQ or LOI is agreed upon and the FCO is signed, we’d be happy to arrange a visit to one of our warehouses that best suits your order specifics. If needed, we can also organize self-pickup of your order from the warehouse under the appropriate Incoterms 2020, making the process as smooth and convenient for you as possible.

Yes, we assist with all necessary documentation to help streamline logistics, compliance, and customs clearance — regardless of the products combination or technical specifications in your order.

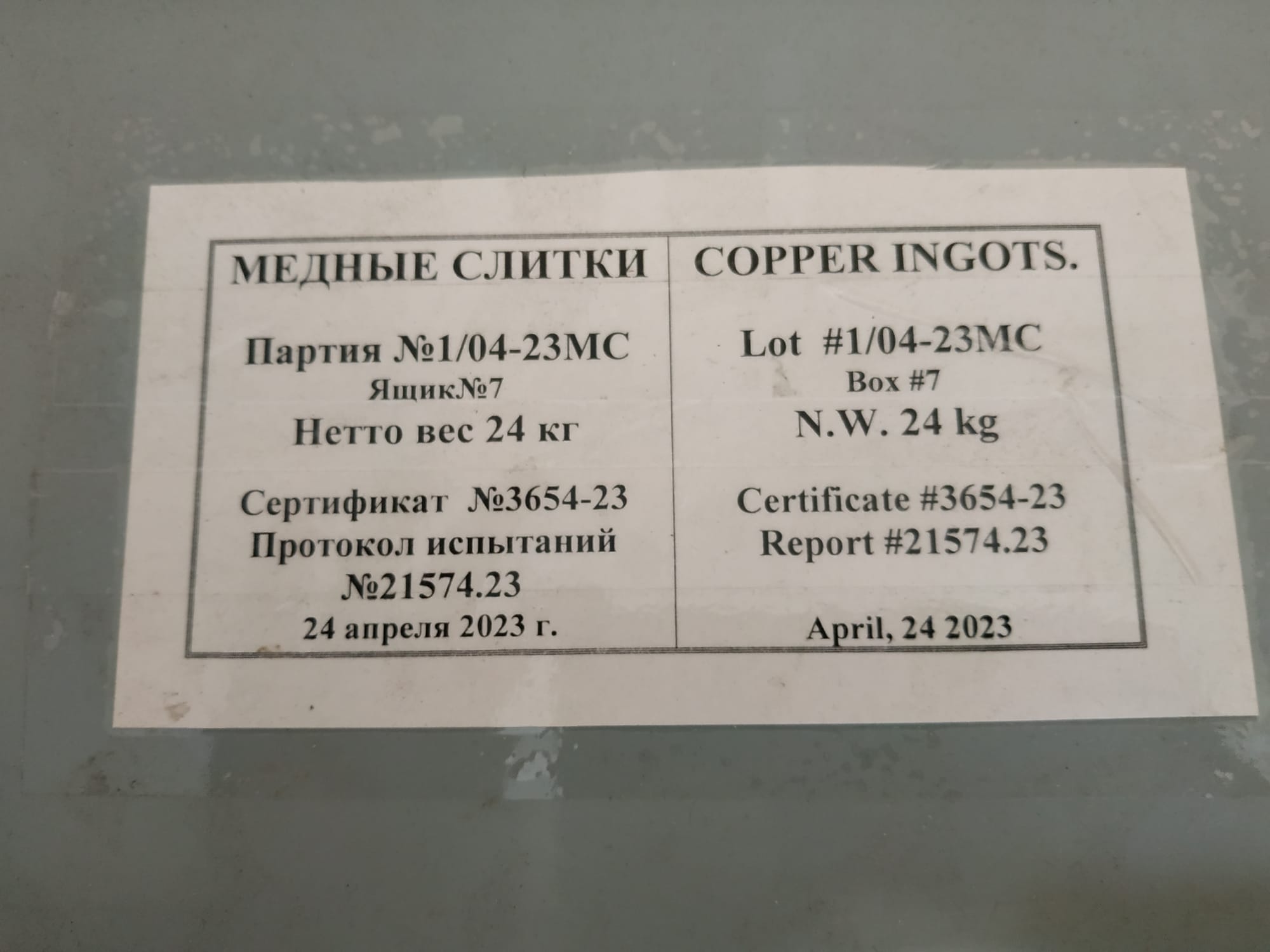

Yes, every delivery includes a lab certificate to verify product purity and ensure batch-to-batch consistency.

Other Products

Ultra High-Purity Copper: Material Profile

Copper is a transition metal with an incomplete electron shell, which allows it to form compounds in multiple valence states — most notably monovalent (Cu⁺) and divalent (Cu²⁺). It melts at 1083 °C, boils at 2600 °C, and has a vapor pressure of 8.6 × 10⁻⁵ mm Hg at 1000 °C. Among metals, copper stands out for its exceptionally high electrical conductivity (1.68 μΩ·cm) and thermal conductivity (0.941 cal/cm·°C·s).

These physical and chemical characteristics, along with excellent mechanical strength and ductility, make high-purity copper indispensable for advanced electronics and precision engineering. However, the performance of copper in such applications is highly sensitive to impurity levels. Even trace amounts of elements like oxygen, chromium, vanadium, manganese, titanium, zirconium, or niobium can degrade its conductive properties.

Product Form and Handling

High-purity copper is typically supplied as trapezoidal ingots — compact, brownish-red blocks engineered for controlled remelting, processing, or storage. While similar in appearance to bars, copper ingots are specific to non-ferrous metallurgy and precision-grade production workflows. Each ingot is individually sealed in inert or protective packaging to prevent surface oxidation and ensure purity preservation during transit and storage.

Why Purity Matters

Industrial demands are shifting toward not just high-quality materials but also stable logistics, clean handling, and ready-to-use formats — especially for export and integration into ultra-sensitive manufacturing chains. Ultra-pure copper enables reliable performance in environments where even microscopic contamination can result in failure or inefficiency.

Applications of Ultra High-Purity Copper (5N–6N)

Ultra high-purity copper, valued for its exceptional electrical conductivity, thermal performance, and biocompatibility, is essential in advanced technologies. For critical industrial and scientific use, purity levels of 99.999% (5N) and above are required. These ultra-pure grades are indispensable in: